VESC hall sensor table and use it to add hall sensors to RC sensorless motor, then nake it work with RC sensored ESC

The HALL sensors provide an indication as to where in the electrical revolution the rotor is. You get enough information to run the motor in BLDC mode depending on the HALL signal values. In BLDC mode there are six phases and the hall sensors conspire to make exactly six combinations.

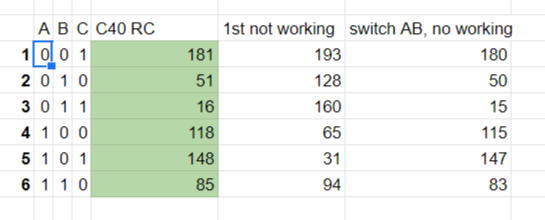

When driving the motor in FOC mode, the position of the rotor during an electrical revolution is thought of as a position on a compass: say 0-360 degrees. Now the three hall signals combine to make a 3-bit number 0-7. So now for each possible combination you note the average compass value when that value is output by the hall sensors. So if during 0-60 the combination 001 or "1" shows on the hall sensors, you put the average "30" in the table at position 1. Now 60-120 teh hall sensors show 011, so you put the average 90 in position 3 in the table.

Now Benjamin decided to save a few bits by instead of counting the revolution in human-convention-units of a degree (i.e. 0-360), he decided to use units of 1.8 degrees. So now that first table-entry does not show "30 degrees" but "17 units-of-1.8 degrees". Except for a bit of rounding this is exactly the same. Close enough for our purpose.

In VESC the e degree is total 200 instead of 360.

Now, there are several things that make this table more regular than random. For example, when you move the rotor half an electrical revolution, all the hall signals will change value. The value will be the ones-complement of what it was before. In three bits the ones complement of x is "7-x". And an electrical revolution is 200(360 degrees), so half a revolution is 100. So table entries 1-6 should differ by 100. Is this difference not precisely 100, that points towards manufacturing tolerances in your motor. But in general it will be pretty close.

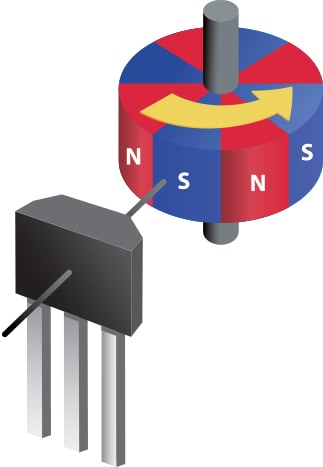

Adding Hall sensor

Ex: 10 poles=5 pole pairs,

10poles 120/5=24 degrees

12poles 120/6=20 Degrees

14,poles 120/7=17.14 Degrees

Few notes on sensor

But you can the escape flux out of motor is enough to trigger hall sensor, you can also fit hall sensors on the outside of motor.

留言

張貼留言